NEW

Application Development in NTC Thermistors for CFR-25JB-52-110K: Key Technologies and Success StoriesNTC (Negative Temperature Coefficient) thermistors, such as the CFR-25JB-52-110K, are essential components in temperature sensing and control applications. Their unique properties make them suitable for a wide range of industries, from consumer electronics to automotive and medical devices. Below, we explore key technologies and notable success stories that highlight the impact of NTC thermistors in various applications.

Key Technologies1. Temperature Sensing and Compensation2. Circuit Design3. Calibration and Compensation Algorithms4. Integration with IoT5. Miniaturization and Packaging1. Consumer Electronics2. Automotive Applications3. Medical Devices4. Industrial Automation5. Smart Home Solutions Success Stories ConclusionThe application development of NTC thermistors like the CFR-25JB-52-110K has led to significant advancements across various industries. By leveraging key technologies such as circuit design, calibration algorithms, and IoT integration, companies have successfully implemented NTC thermistors in innovative ways, resulting in improved efficiency, accuracy, and user experience. As technology continues to evolve, the potential for NTC thermistors in new applications remains vast, paving the way for further innovations in temperature sensing and control.

Application Development in Single Bipolar Transistors for MM74HC259N: Key Technologies and Success StoriesThe MM74HC259N is a versatile high-speed CMOS logic device that serves as an 8-bit addressable latch, making it a popular choice in various digital applications such as data storage, signal processing, and control systems. When integrating single bipolar junction transistors (BJTs) with the MM74HC259N, several key technologies and success stories emerge, showcasing the potential of this combination in real-world applications.

Key Technologies1. Bipolar Junction Transistors (BJTs)2. Logic Level Shifting3. Signal Conditioning4. Integrated Circuit Design5. Feedback and Control Systems1. Consumer Electronics2. Industrial Automation3. Robotics4. LED Display Systems5. Telecommunications Success Stories ConclusionThe integration of single bipolar transistors with the MM74HC259N presents a wealth of opportunities for application development across various industries. By harnessing the strengths of both BJTs and CMOS devices, developers can create efficient, reliable, and high-performance systems tailored to specific needs. As technology continues to advance, the synergy between BJTs and CMOS devices like the MM74HC259N will remain pivotal in the design of innovative electronic solutions, driving progress in fields ranging from consumer electronics to industrial automation and telecommunications.

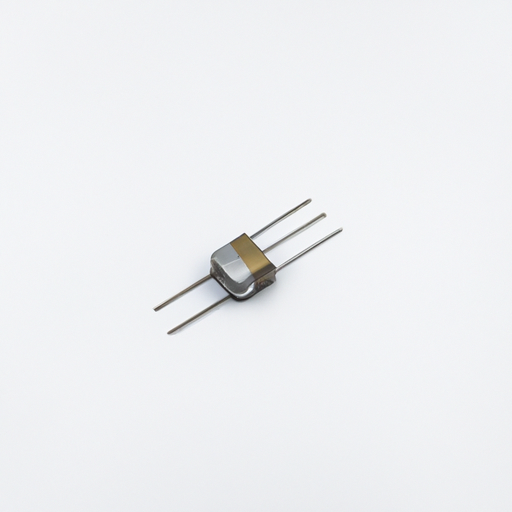

CFR-50JB-52-1K8 Bipolar Transistor Arrays: Core Functional Technologies and Application Development CasesThe CFR-50JB-52-1K8 is a specific model of bipolar transistor array that exemplifies the advantages of integrating multiple transistors into a single package. This technology is pivotal in various electronic applications, providing compactness, efficiency, and the ability to manage multiple signals simultaneously. Below, we delve into the core functional technologies and application development cases that highlight the effectiveness of bipolar transistor arrays, including the CFR-50JB-52-1K8.

Core Functional Technologies1. Integration of Multiple Transistors2. High-Speed Switching3. Current Amplification4. Thermal Stability5. Low Noise Operation1. Audio Amplification2. Signal Processing3. Switching Regulators4. Motor Control5. RF Applications6. Sensor Interfaces Application Development Cases ConclusionBipolar transistor arrays like the CFR-50JB-52-1K8 are integral to modern electronic systems, offering a blend of compact design, high performance, and versatility. Their applications span diverse industries, from consumer electronics to industrial automation, underscoring their importance in contemporary technology. As advancements in semiconductor technology continue, the development of more sophisticated bipolar transistor arrays will likely lead to innovative applications and enhanced performance in existing systems. The CFR-50JB-52-1K8 stands as a testament to the capabilities and potential of bipolar transistor arrays in driving the future of electronics.

Application Development in Power Driver Modules for CFR-25JB-52-10R: Key Technologies and Success StoriesDeveloping applications for Power Driver Modules (PDMs) such as the CFR-25JB-52-10R requires a comprehensive understanding of various technologies and methodologies. These modules are critical in sectors like aerospace, automotive, and industrial automation, where performance, reliability, and efficiency are essential. Below is an overview of key technologies and notable success stories in the application development of PDMs.

Key Technologies1. Power Electronics2. Thermal Management3. Control Algorithms4. Embedded Systems5. Simulation and Modeling6. Communication Protocols7. Safety Standards1. Aerospace Applications2. Electric Vehicles (EVs)3. Industrial Automation4. Renewable Energy Systems5. Consumer Electronics Success Stories ConclusionThe development of applications for Power Driver Modules like the CFR-25JB-52-10R necessitates a multidisciplinary approach that encompasses power electronics, thermal management, control systems, and compliance with safety standards. The success stories across various industries underscore the potential of PDMs to drive innovation, enhance efficiency, and improve product performance. As technology continues to advance, the role of PDMs is expected to expand, paving the way for new applications and opportunities in the future.

Application Development for CFR-50JB-52-10K: Key Technologies and Success StoriesDeveloping applications for specialized purposes, such as CFR-50JB-52-10K, involves a focus on specific regulatory, operational, or technical requirements, particularly in industries like nuclear power. Below is an overview of key technologies and success stories in application development for such specialized purposes.

Key Technologies1. Regulatory Compliance Software2. Data Analytics and Reporting3. Simulation and Modeling Tools4. IoT and Sensor Technologies5. Cybersecurity Solutions6. Mobile and Web Applications7. Blockchain for Traceability1. Nuclear Power Plant Compliance Management2. Predictive Maintenance in Energy Sector3. Real-Time Monitoring Systems4. Cybersecurity Enhancements5. Blockchain for Regulatory Reporting Success Stories ConclusionApplication development for special purposes like CFR-50JB-52-10K requires a deep understanding of regulatory requirements, operational needs, and the latest technologies. By leveraging advanced tools and methodologies, organizations can enhance compliance, improve operational efficiency, and ensure safety in regulated environments. Success stories from various sectors illustrate the potential benefits of these technologies in achieving regulatory compliance and operational excellence, paving the way for future innovations in the field.

Overview of ECQ-P1H153GZ IGBT ArraysThe ECQ-P1H153GZ IGBT array is a notable example of advanced IGBT technology, designed to meet the demands of high-performance power electronics applications. This device integrates several core functional technologies that enhance its effectiveness in various sectors, including renewable energy, electric vehicles, and industrial automation.

Core Functional Technologies1. High Voltage and Current Handling2. Fast Switching Speed3. Thermal Management4. Integrated Protection Features5. Modular Design1. Renewable Energy Inverters2. Electric Vehicle (EV) Drives3. Industrial Motor Drives4. Power Supplies5. HVAC Systems6. Railway Traction Systems Application Development Cases ConclusionThe ECQ-P1H153GZ IGBT array represents a significant advancement in IGBT technology, offering high performance, reliability, and versatility across a wide range of applications. As industries increasingly prioritize energy efficiency and sustainability, the role of IGBT arrays in power electronics will continue to expand, driving innovation in sectors such as renewable energy, electric vehicles, and industrial automation. The integration of advanced features and capabilities in devices like the ECQ-P1H153GZ positions them as essential components in the future of power electronics.

Application Development in JFETs for CFR-25JB-52-100R: Key Technologies and Success StoriesThe CFR-25JB-52-100R is a 100-ohm, 1/4 watt, 1% tolerance thick film resistor, which, while not directly related to JFETs (Junction Field Effect Transistors), plays a significant role in circuits where JFETs are utilized. Below, we explore the key technologies in JFET applications and highlight success stories that demonstrate their effectiveness in conjunction with precision resistors like the CFR-25JB-52-100R.

Key Technologies in JFET Applications1. High Input Impedance Amplifiers 2. Analog Signal Processing 3. Voltage-Controlled Resistors (VCRs) 4. Switching Applications 5. Low-Noise Amplifiers 6. Buffer Stages 1. High-Fidelity Audio Equipment 2. Precision Measurement Instruments 3. Telecommunications 4. Medical Devices 5. Consumer Electronics Success Stories ConclusionWhile the CFR-25JB-52-100R resistor is not a JFET, it is often used in circuits that leverage the advantages of JFETs for various applications. The combination of JFETs and precision resistors is essential for achieving high performance in analog signal processing, instrumentation, and other electronic applications. The success stories illustrate the versatility and effectiveness of JFETs in modern electronic design, particularly when paired with high-quality components like the CFR-25JB-52-100R. This synergy is crucial for developing reliable, high-performance electronic systems across various industries.

Overview of CFR-25JB-52-100K Single Zener DiodesThe CFR-25JB-52-100K is a specific model of a single Zener diode, a semiconductor device that allows current to flow in the reverse direction when a specific voltage, known as the Zener voltage, is reached. Zener diodes are widely used for voltage regulation, protection, and reference applications in electronic circuits.

Core Functional Technology of Zener Diodes1. Voltage Regulation 2. Reverse Breakdown Operation 3. Temperature Stability 4. Low Noise 5. Fast Response Time 1. Voltage Regulation Circuits2. Overvoltage Protection3. Reference Voltage Sources4. Signal Clipping5. LED Drivers1. Power Supply Design2. Transient Voltage Suppression3. Analog Signal Conditioning4. LED Circuit Protection Applications of Single Zener Diodes Development Cases ConclusionThe CFR-25JB-52-100K single Zener diode is a versatile component that plays a critical role in various electronic applications. Its ability to regulate voltage, provide overvoltage protection, and serve as a reference voltage source makes it an essential part of modern electronic design. Understanding its core functional technology and application cases can help engineers effectively integrate Zener diodes into their projects, enhancing performance and reliability. Additional ConsiderationsWhen selecting a Zener diode for a specific application, engineers should consider factors such as the Zener voltage rating, power dissipation, and temperature coefficient. Proper thermal management and circuit design are also essential to ensure the reliability and longevity of the Zener diode in its intended application.

Application Development in Diode Arrays for CFR-50JB-52-100K: Key Technologies and Success StoriesDiode arrays, particularly in the context of applications like the CFR-50JB-52-100K, play a crucial role across various sectors, including telecommunications, medical devices, and industrial automation. Below is an overview of key technologies and notable success stories related to diode arrays.

Key Technologies1. High-Power Diode Lasers2. Wavelength Division Multiplexing (WDM)3. Optical Coherence Tomography (OCT)4. Solid-State Lighting5. Sensor Applications6. Thermal Management1. Telecommunications2. Medical Imaging3. Industrial Laser Systems4. Solid-State Lighting5. Environmental Monitoring Success Stories ConclusionThe development of applications in diode arrays, particularly for products like the CFR-50JB-52-100K, exemplifies the integration of advanced technologies and innovative solutions across various industries. The success stories highlight the versatility and significant impact of diode arrays in enhancing performance, efficiency, and capabilities in telecommunications, medical imaging, industrial applications, and beyond. As technology continues to advance, the potential for diode arrays is expected to expand, paving the way for new applications and improvements in existing systems.

Application Development in RF Diodes for CFR-50JB-52-100R: Key Technologies and Success StoriesThe CFR-50JB-52-100R is a specialized RF (Radio Frequency) diode that plays a crucial role in various applications, including RF amplification, signal processing, and other RF-related technologies. This document outlines the key technologies associated with the CFR-50JB-52-100R and highlights notable success stories that demonstrate its impact across different industries.

Key Technologies1. High-Frequency Performance2. Low Noise Characteristics3. Power Handling Capability4. Temperature Stability5. Integration with Other Components6. Advanced Packaging Techniques1. Telecommunications2. Broadcasting3. Radar Systems4. Medical Imaging5. Consumer Electronics Success Stories ConclusionThe CFR-50JB-52-100R RF diode exemplifies the advancements in RF technology, showcasing its versatility across various industries. By leveraging key technologies such as high-frequency performance, low noise characteristics, and robust power handling, developers have successfully integrated these diodes into critical applications, leading to enhanced performance and reliability in RF systems. As technology continues to evolve, the role of RF diodes will remain pivotal in driving innovation across telecommunications, broadcasting, medical imaging, and beyond. The success stories associated with the CFR-50JB-52-100R highlight its importance in shaping the future of RF applications and its contribution to various sectors.

Application Development in Variable Capacitance (Varicaps, Varactors) for CFR-25JB-52-1R8: Key Technologies and Success StoriesVariable capacitance diodes, commonly known as varicaps or varactors, are essential components in modern electronics, particularly in RF and microwave applications. The CFR-25JB-52-1R8 designation likely refers to a specific varactor model, which may be utilized in various applications due to its tunable capacitance characteristics. Below is an overview of the key technologies driving varicap development and notable success stories in their application.

Key Technologies in Varicap Development1. Material Science Advances2. Integrated Circuit (IC) Design3. Tuning Techniques4. Simulation and Modeling5. Packaging Innovations1. Tunable RF Filters2. Phase-Locked Loops (PLLs)3. Voltage-Controlled Oscillators (VCOs)4. Television Tuners5. Automotive Applications6. Consumer Electronics Success Stories in Varicap Applications ConclusionThe development of variable capacitance diodes has significantly influenced various industries, particularly telecommunications, automotive, and consumer electronics. Ongoing advancements in materials, IC design, and packaging technologies continue to enhance the performance and applicability of varactors. As the demand for compact, efficient, and versatile electronic devices grows, the role of varactors in application development will likely expand, leading to new innovations and success stories in the field. The CFR-25JB-52-1R8 and similar components will remain pivotal in driving these advancements forward.

Application Development in Single Diodes: Key Technologies and Success StoriesWhile the CFR-25JB-52-1M8 is a resistor, the world of single diodes encompasses a wide range of technologies and applications that are critical in modern electronics. Below, we explore key technologies in single diodes and highlight notable success stories that illustrate their impact across various industries.

Key Technologies in Single Diodes1. Silicon Diodes2. Schottky Diodes3. Zener Diodes4. Photodiodes5. High-Temperature Diodes6. Silicon Carbide (SiC) and Gallium Nitride (GaN) Diodes1. Power Supply Innovations2. Solar Energy Optimization3. Telecommunications Advancements4. Automotive Industry Transformation5. Consumer Electronics Reliability Success Stories ConclusionThe development and application of single diodes have profoundly influenced various sectors, including consumer electronics, renewable energy, telecommunications, and automotive industries. As technology continues to advance, the focus on efficiency, miniaturization, and enhanced performance will drive further innovations in diode applications. If you have specific applications or technologies in mind, feel free to ask for more detailed information!